3. Mechanical Equipment

Defects in the mechanical components can generally be identified from the following;

• High vibrations

• Noise

• Overheating

• Inspection

Vibration may take place due to loose nuts and bolts, under - tensioned belts. damages in the turbine and

worn out bearings. Tighten up loose nuts and bolts. Check the turbine and see whether it is damaged or

loose. If there is a problem with the bearings they may have to be replaced with the help of a competent

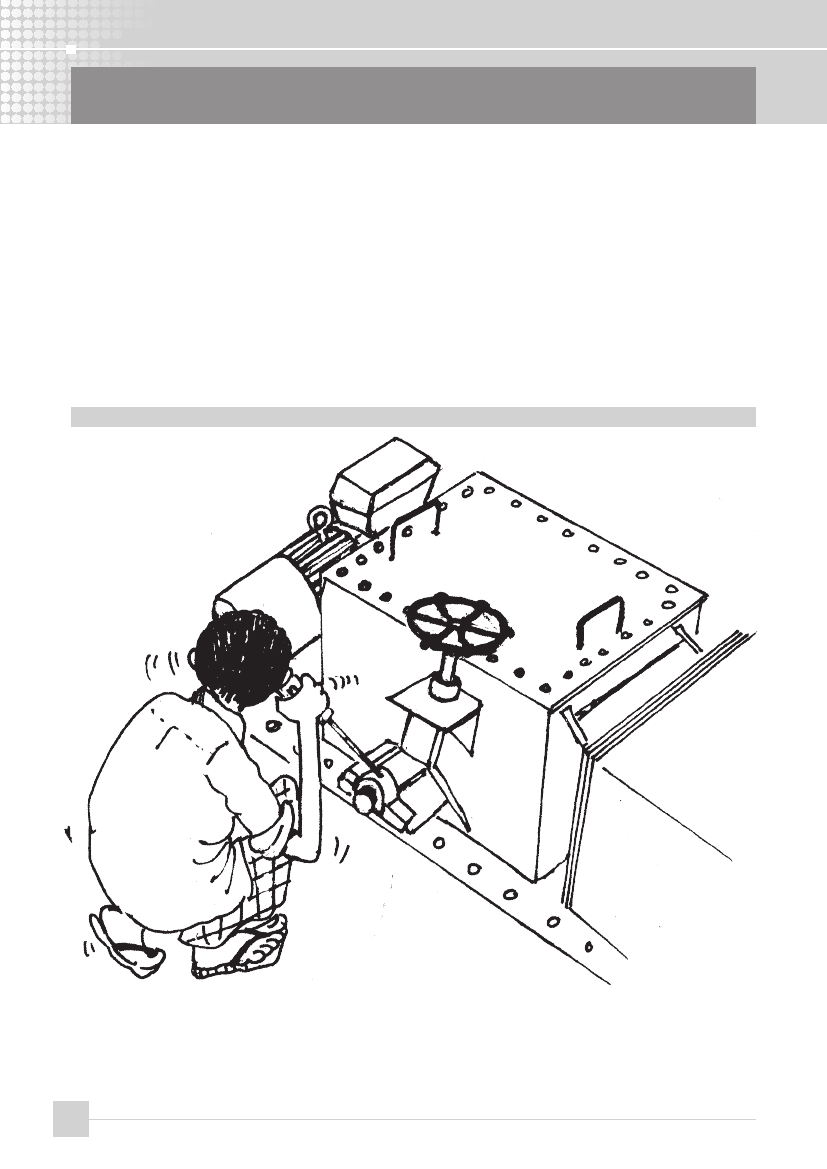

technician. Worn out bearings can be identified using a long screw driver as shown in drawing below.

Checking the bearings for Vibration

A smooth sound while running indicates that the bearings function smoothly while a coarse or sharp

sound indicates that the bearings have some problem.

14